When use ESD flooring?

Generally, you will need an ESD floor if you are manufacturing, repairing, servicing, handling or using equipment that is susceptible to damage from electrostatic discharge or if you deal with combustible materialsl, It is widely used in electronic, microelectronic and telecommunication environments, network floors, clean rooms, computer rooms and other places where precision instruments and equipment are in operation. ESD vinyl flooring is divided into two types:ESD tile and ESD sheet.

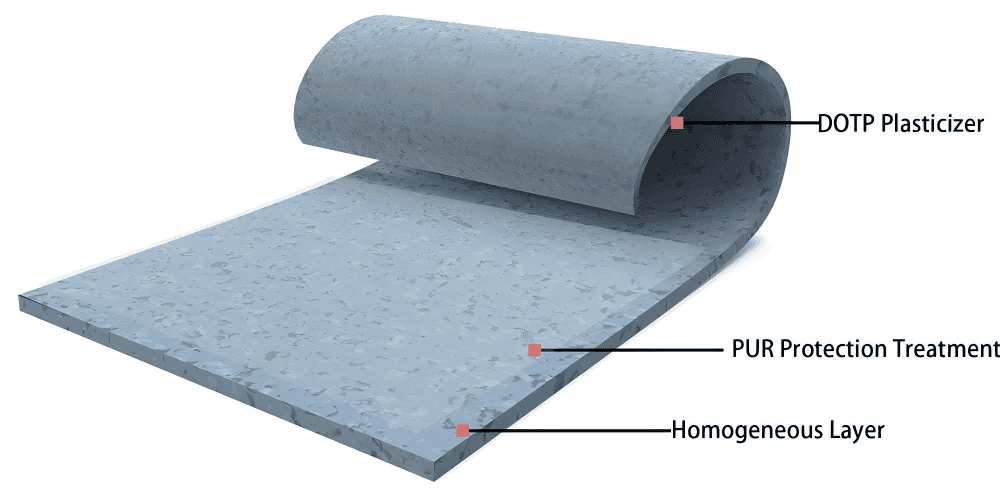

ESD Tiles and ESD Rolls (Sheets) are both homogeneous structures, which is why they have chemical resistance, antibacterial, antifouling, and durability. They both have two resistance characteristics, conductive (10^4-10^6Ω) and static dissipative (10^6-10^9Ω).

The difference between ESD tiles and ESD Rolls(Sheet)?

The difference between ESD tiles and ESD Rolls(Sheet)?

The raw materials of tile and sheet are almost the same; materials include polyvinyl chloride resin, conductive materials, stabilizers, plasticizers, pigments, and other auxiliary materials. But their production processes and equipment are entirely different.

Next, we discuss their differences from the following six points:

1. Difference in size

2. Difference in production

3. Difference in the implementation of conductivity

4. Difference in application

5. Difference in installation

6. Difference in price

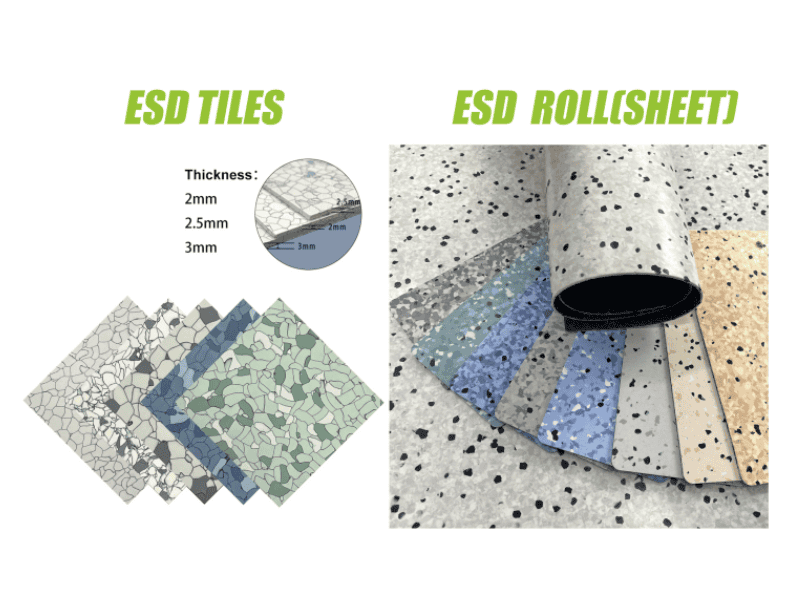

1. Difference in size

ESD tile :

Size: 600×600mm, 608×608mm, 610×610mm, 900×900mm,

Thickness can be 2mm, 2.5mm, and 3mm.

ESD Roll(sheet):

Size: 2×20m, 2×15m,

Thickness: 2mm, 2.5mm, 3mm.

2. Difference in production

ESD Tiles produce machine is vulcanizing press machine, and production processes include granulation, tile making(hot press), board split, polishing, and punching. .

ESD Rolls produce machine is a belt press machine, and production processes include granulation, sheet making(belt press), lacquering, embossing, and relaxation.

Antistatic PVC flooring coils are semi-rigid coils formed by mixing conductive carbon black into polyvinyl chloride particles and then molding them at high temperatures using a hot press. Since the antistatic floor is made of a homogeneous and transparent material, it ensures that the conductive network formed by the conductive carbon black is interconnected, thereby achieving a permanent antistatic effect. Antistatic PVC floor sheets are made by hot pressing polyvinyl chloride resin, shrinkage enhancer, stabilizer, coupling agent and conductive material. It uses the conductive network formed between the interfaces of plastic particles to conduct electricity and has a permanent antistatic effect.

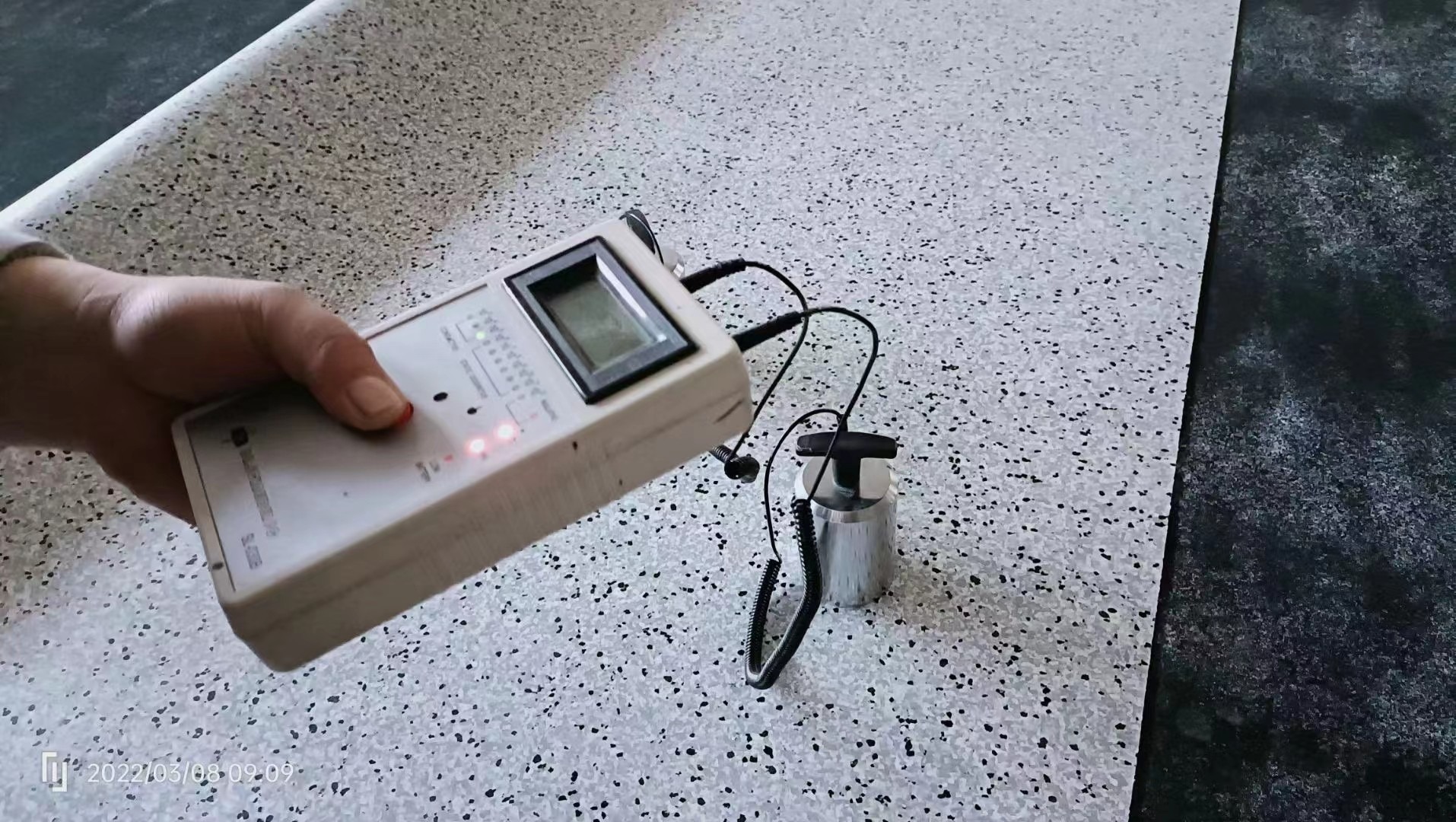

3. Difference in the implementation of conductivity

Antistatic PVC flooring coils are semi-rigid coils formed by mixing conductive carbon black into polyvinyl chloride particles and then molding them at high temperatures using a hot press. Since the antistatic floor is made of a homogeneous and transparent material, it ensures that the conductive network formed by the conductive carbon black is interconnected, thereby achieving a permanent antistatic effect. Antistatic PVC floor sheets are made by hot pressing polyvinyl chloride resin, shrinkage enhancer, stabilizer, coupling agent and conductive material. It uses the conductive network formed between the interfaces of plastic particles to conduct electricity and has a permanent antistatic effect.The difference in craftsmanship also creates different surface patterns on ESD tiles and ESD rolls, which can be distinguished at a glance.

4. Difference in application

From our experience, big projects like electronic products workshops prefer ESD tile except for better price, tile is also easier to maintain and replace.

Small areas like hospital operation rooms prefer ESD roll. Roll colors are more decorative Antibacterial performance is also better.

5. Difference in installation

The installation tools and accessories for tiles and sheets are the same. (conductive glue/adhasive, welding rod, copper tape, and so on.for construction, rolls are relatively simpler than sheets. In terms of later maintenance, sheets are more convenient than rolls.

6. Difference in price

In terms of price, since PVC static floor rolls are made on a homogeneous basis, the price of the rolls is slightly more expensive than that of the sheets.

The PVC content of anti-static PVC floor rolls is much higher than that of sheets, so the wear resistance is slightly better than that of sheets, and the service life is naturally longer than that of sheets.