How to correctly select and apply the anti-static PVC flooring resistor?

10^4-10^6Ω/10^6-10^9Ω In static-sensitive environments such as modern electronics industries, medical facilities, laboratories, and data processing centers, the choice of antistatic flooring is crucial. Many people are confused by the two resistance specifications: “10×10^4Ω—10×10^6Ω“ and “10×10^6Ω—10×10^9Ω“. This article will provide an in-depth analysis of the differences between these two specifications, their applicable scenarios, and the selection criteria. Technical […]

Winter-Proof Flexibility: The PVC Flooring That Stays Soft

With rising expectations for quality, homogeneous vinyl flooring is now favored in hospitals, schools, malls, and factories for its wear resistance, antibacterial properties, and overall performance. However, many users notice that as October the month with the most significant temperature fluctuations and lower ambient temperatures arrives, the flooring underfoot seems to become “cold and stiff”: […]

How to installation of Homogeneous vinyl flooring

Installing homogeneous flooring is a highly specialized task, requiring extremely high standards for both substrate quality and construction techniques. If you’re not an experienced professional, we strongly recommend hiring a professional installation team to ensure the longevity and effectiveness of the flooring. This guide will outline both the professional procedures and precautions to ensure you […]

How to Identify the Quality of Homogeneous PVC Flooring

Homogeneous PVC flooring is a highly durable type of PVC flooring made by blending pure PVC with fillers, plasticizers, and other additives. However, poor-quality versions can wear out quickly. To distinguish high-quality homogeneous PVC flooring, consider the following key factors: 1.Wear Resistance Homogeneous PVC flooring consists of PVC, fillers, and plasticizers—not pure PVC. Wear resistance […]

Unique flooring for hospitals and schools!

The flooring choice is crucial in places with high traffic and high hygiene requirements, such as hospitals and schools. Traditional flooring materials such as tiles, solid wood, or laminate often cannot meet the needs of high-intensity use and strict cleaning. Homogeneous Vinyl Flooring has become the first choice for medical and educational institutions due to […]

Anti-static PVC Flooring Market in 2024 and Market Trend in 2025

Anti-static PVC flooring is a special flooring material widely used in electronic manufacturing, data centers, medical facilities, laboratories, and other fields. Its primary function is to protect sensitive equipment and products from electrostatic discharge (ESD) damage through conductive properties or static dissipative. With the rapid development of the global electronics and high-tech industries, the anti-static […]

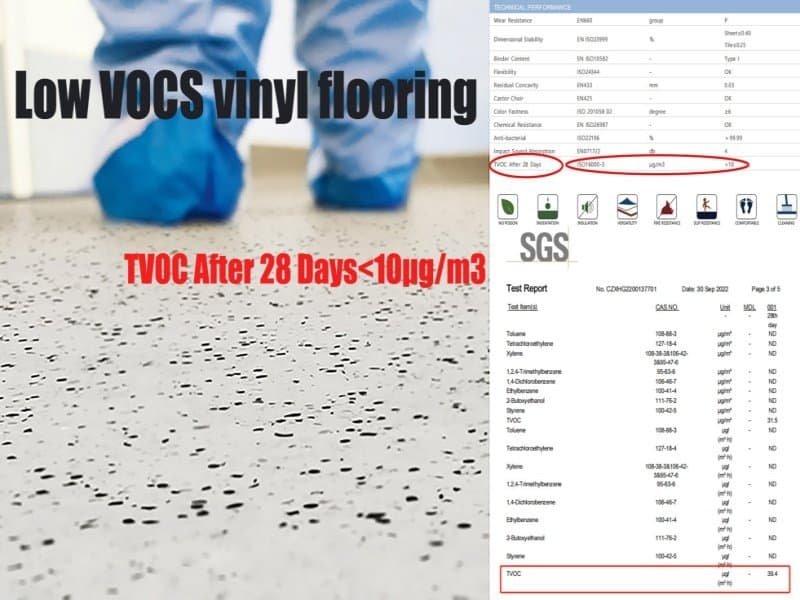

Low VOCs for better indoor air quality with vinyl flooring!

VOCs are a significant issue in many industries, especially in flooring solutions. These compounds readily evaporate into gases and are widely found in building materials and products. Despite their ubiquity, VOCs significantly impact health, safety, and the environment. So, how do you buy low-VOC vinyl flooring? VOC is one of the three types of pollution […]

What is ESD flooring?

Why use ESD flooring ? Where require ESD flooring? What is ESD flooring? ESD flooring stands for Electrostatic Discharge. ESD is a grounded static dissipative floor or conductive floor covering with a resistance between 2.5 x 104 and 1.0 x 109 ohms. This only means that the floor itself does not generate static electricity; it […]

Advantages and Disadvantages of homogeneous vinyl flooring

Advantages Homogeneous vinyl flooring uses PVC as its raw material in production and does not contain recycled PVC, so it contains less plasticizer. Environmentally friendly and healthy: The wear life is generally longer than that of multi-layer heterogeneous vinyl flooring: According to the classification of EN685, M grade and above can be used in 34/43 […]

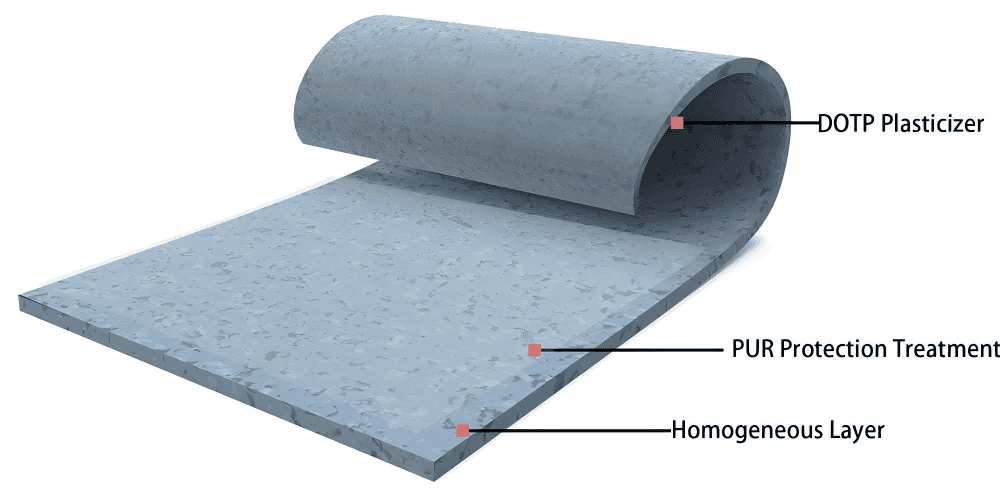

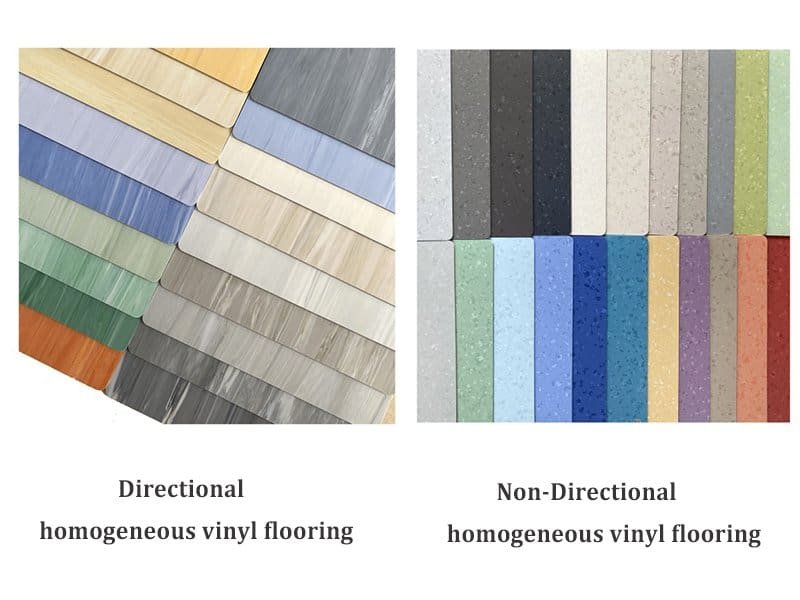

What is homogeneous vinyl flooring?

Homogeneous vinyl flooring is made from a single layer of mixed materials from top to bottom, primarily composed of PVC resin powder, calcium carbonate, and stabilizers. Due to its uniform composition throughout, homogeneous vinyl flooring functions as an ultra-thick wear-resistant layer. However, the wear resistance levels of homogeneous vinyl flooring can vary. This article will […]