Advantages

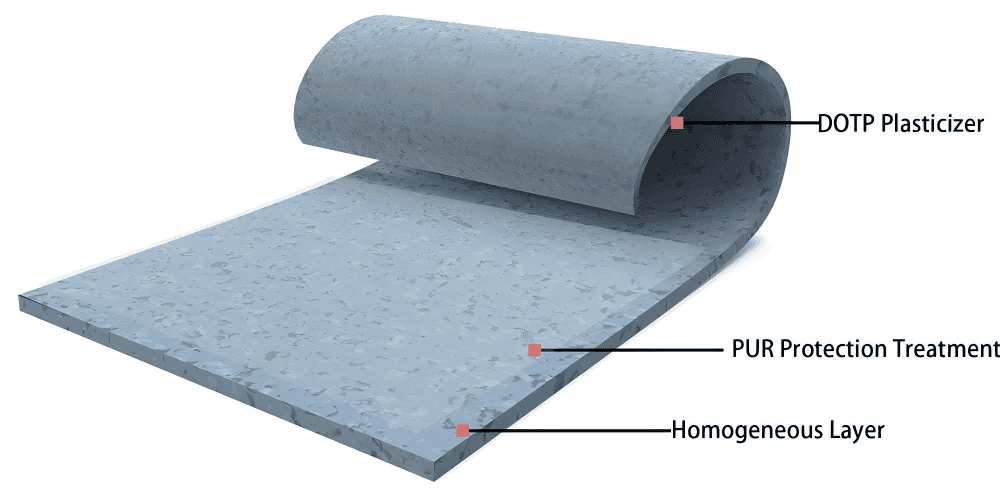

Homogeneous vinyl flooring uses PVC as its raw material in production and does not contain recycled PVC, so it contains less plasticizer.

Environmentally friendly and healthy:

The wear life is generally longer than that of multi-layer heterogeneous vinyl flooring: According to the classification of EN685, M grade and above can be used in 34/43 (extremely high-traffic commercial places/high-traffic industrial places), and the cigarette butt resistance is better than that of multi-layer heterogeneous vinyl flooring: Because it contains stone powder, the floor surface has better scald resistance, and when scald marks appear on the surface, they can be removed by grinding.

Severe scratches can be repaired by welding:

When deep grooves less than 4mm appear on the surface of the floor, you can use the homogeneous property to cut 3mm narrow strips of the floor, weld the narrow strips into the deep grooves using a hot melt welding process, and then smooth the welds. After waxing, it can be restored to its original state.

Strong welds:

Since the entire groove depth of the floor can provide welding strength and the welds are not easy to crack, they are more reliable in laboratories, pharmaceutical factories, operating rooms, etc.

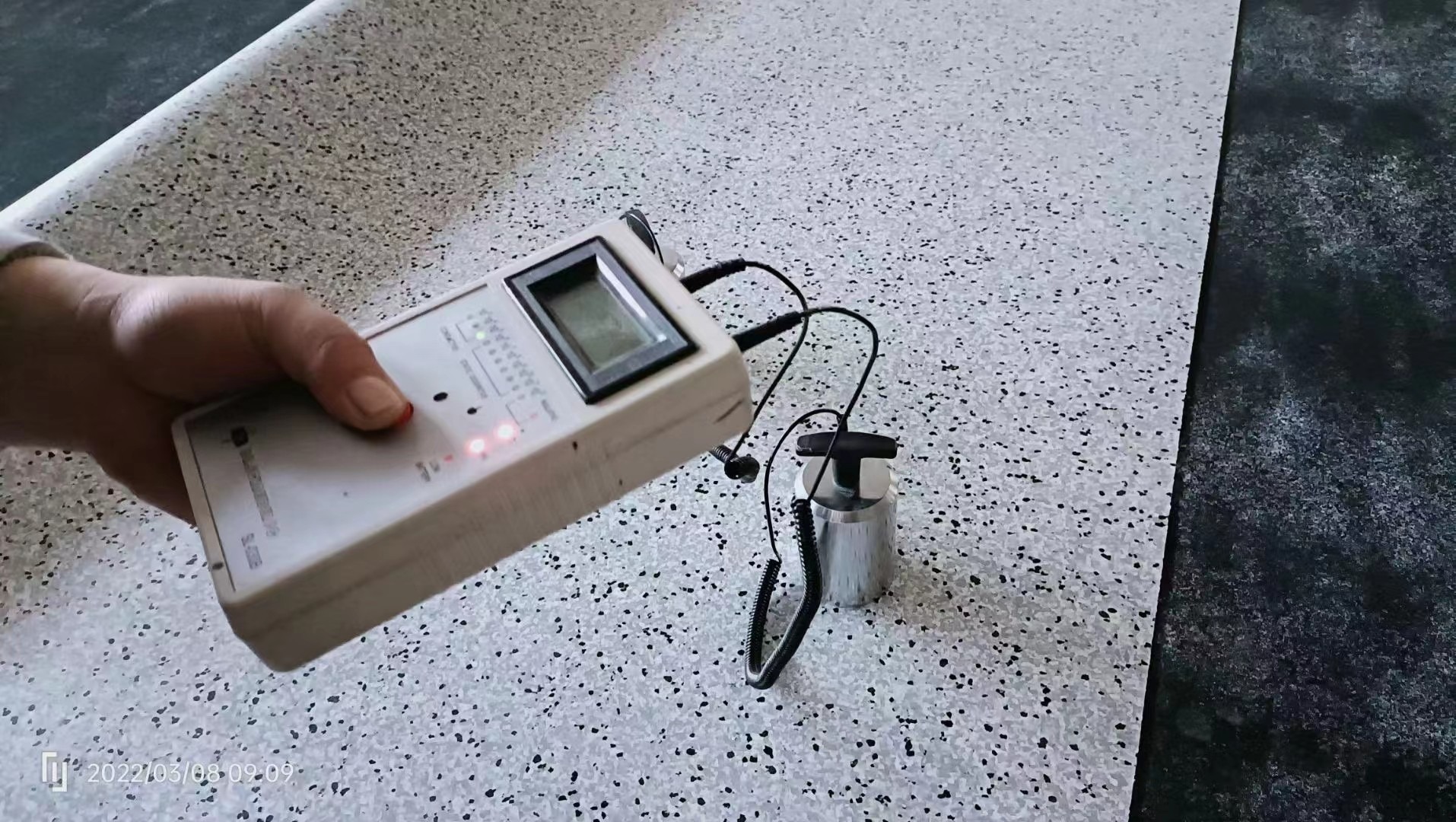

High-quality products are equipped with PUR wax-free technology and have low maintenance costs.

Disadvantages

It needs regular waxing and maintenance. It contains a certain amount of stone powder and has no PVC wear-resistant layer on the surface. Its fire resistance is not as good as that of heterogeneous vinyl flooring.

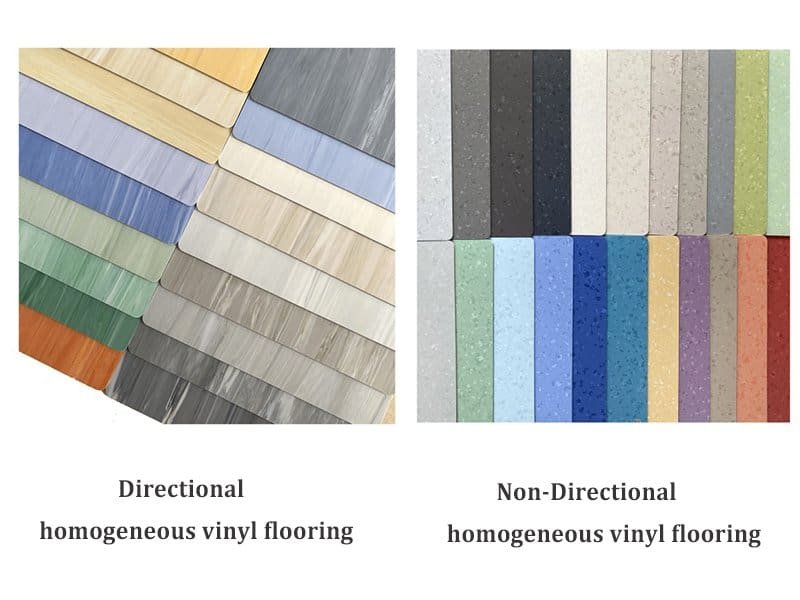

Differences between Directional and NON-Directional homogeneous vinyl flooring

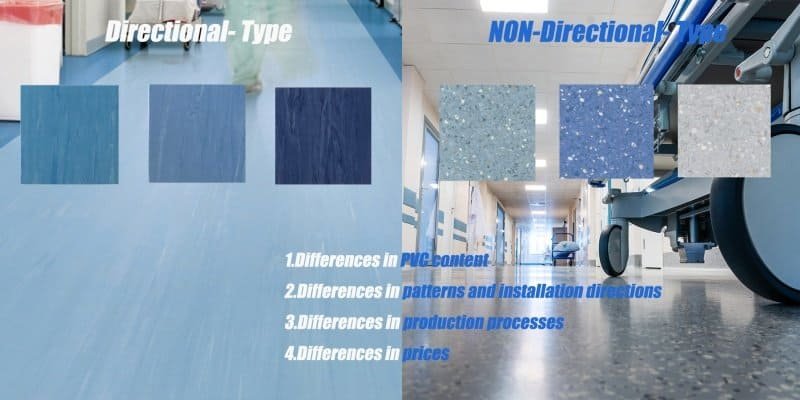

1. Difference in PVC content: Homogeneous vinyl flooring, a type of PVC flooring, is primarily composed of PVC, calcium powder, and additional components. However, the PVC content in directional homogeneous vinyl flooring is significantly lower than in non-directional homogeneous vinyl flooring. This disparity has practical implications for the flooring’s performance.

2. Difference in patterns: Directional homogeneous vinyl flooring has vertical stripe patterns, which are pull patterns. It has a very obvious directionality and can only be laid in one direction. If the direction changes, there will be obvious pattern dislocation and color difference. The non-directional homogeneous vinyl flooring has densely packed floral patterns of different colors with no apparent sense of direction. There will be no noticeable difference when laid in various directions (but try to lay in the same direction).

3. Difference in process: Directional homogeneous vinyl flooring adopts a one-time molding process, while non-directional homogeneous vinyl flooring adopts a multiple molding process. The one-time molding process is simple and fast, but the density is very low, while the multiple molding process is complicated but greatly increases the density, which greatly improves the wear resistance and prolongs the service life.

4. Price difference: When it comes to cost, directional homogeneous vinyl flooring, whether domestic or imported, is generally more budget-friendly than non-directional homogeneous vinyl flooring. This cost disparity is an important factor to consider when choosing the right flooring for your project.