How is vinyl sheet flooring made?

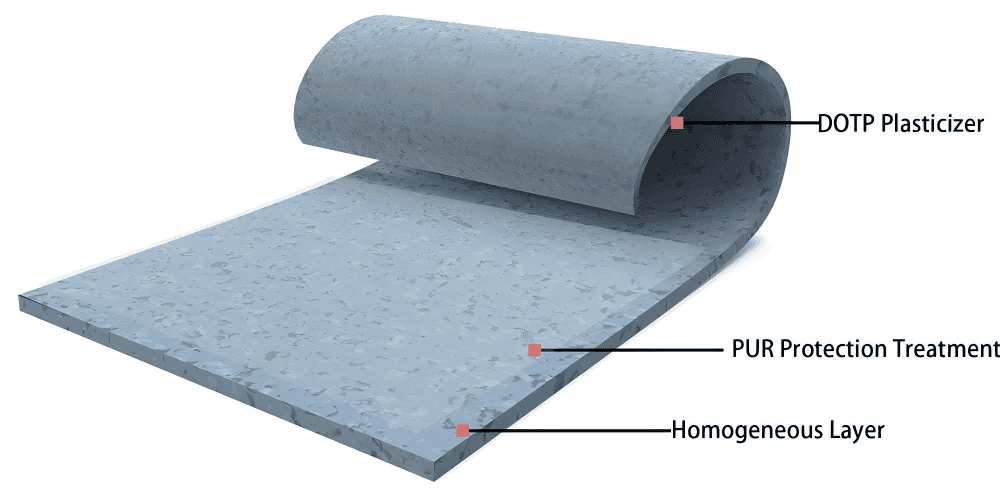

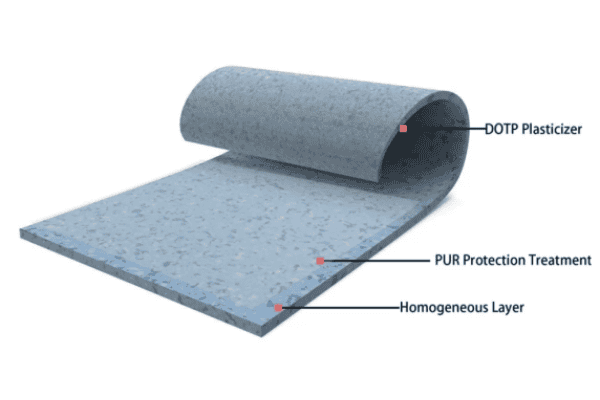

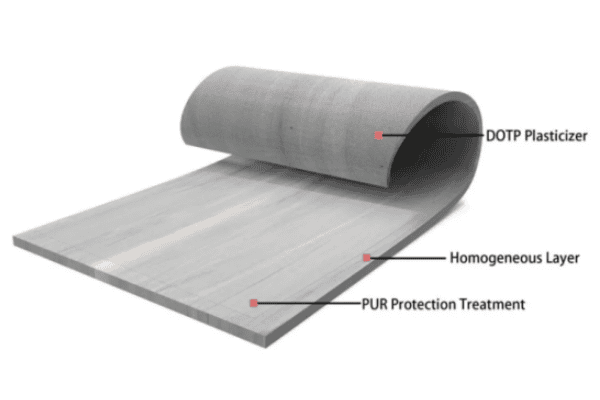

First, the raw materials which include limestone, polyvinyl chloride,plasticizer, stabilizers and pigments, are thoroughly mixed. After mixing, the material is produced through multiple stages including calendering, consolidation and/or lamination, and is finally consolidated and formed into sheets. The sheets are then cooled, formed into rolls and finally packaged.

Why hospitals prefer homogeneous floors?

Hospitals want flooring solutions that are environmentally friendly, antibacterial, wear-resistant, easy to clean and affordable. PVC flooring is an important part of building a hospital environment. The rich colors of PVC flooring are used to meet innovation and design. Through the design and matching of graphics and colors of PVC flooring, a pattern with a “visual therapy” effect can be created. Many other materials cannot do this, but PVC flooring is a floor material with unlimited room for development.

What is the purpose of plasticizers in PVC flooring?

The properties of plasticizers mainly include the following: plasticizing efficiency, compatibility, cold resistance, durability, heat resistance, insulation, flame retardancy and hygiene. This is exactly related to the homogeneous floor performance required in health centers.

What is the difference between using DOTP and DOP in pvc flooring?

A:DOP is an ortho-benzene plasticizer and does not meet EU requirements. DOTP is a paraben product and meets EU requirements.

B:From the commercial point of view, DOP has been preferred, of course when it is possible to use it, due to its higher solvation with PVC and faster absorption during the mixing process (fastest drying). But from the perspective of the product itself, DOTP has better electrical insulation properties, its volume resistivity is more than ten times that of DOP, and its electrical properties are more stable after being heated. Under the same conditions, the residual amount will be only half of that of DOP. At the same time, the plasticized PVC resin has better low-temperature flexibility and low-temperature resistance, and is more suitable for high-temperature PVC production, will be better.

C:The cost difference between DOP and DOTP is not big. If it is beneficial to the performance of the product, why not use it?

As a new plasticizer that complies with EU requirements,DOTP has long become a basic parameter requirement for many customers. Especially for some professional large-scale projects, for more product information, please click this link or leave us a message through this link: https://doublehorseflooring.com/contact-us/.