Homogeneous PVC flooring is a highly durable type of PVC flooring made by blending pure PVC with fillers, plasticizers, and other additives. However, poor-quality versions can wear out quickly. To distinguish high-quality homogeneous PVC flooring, consider the following key factors:

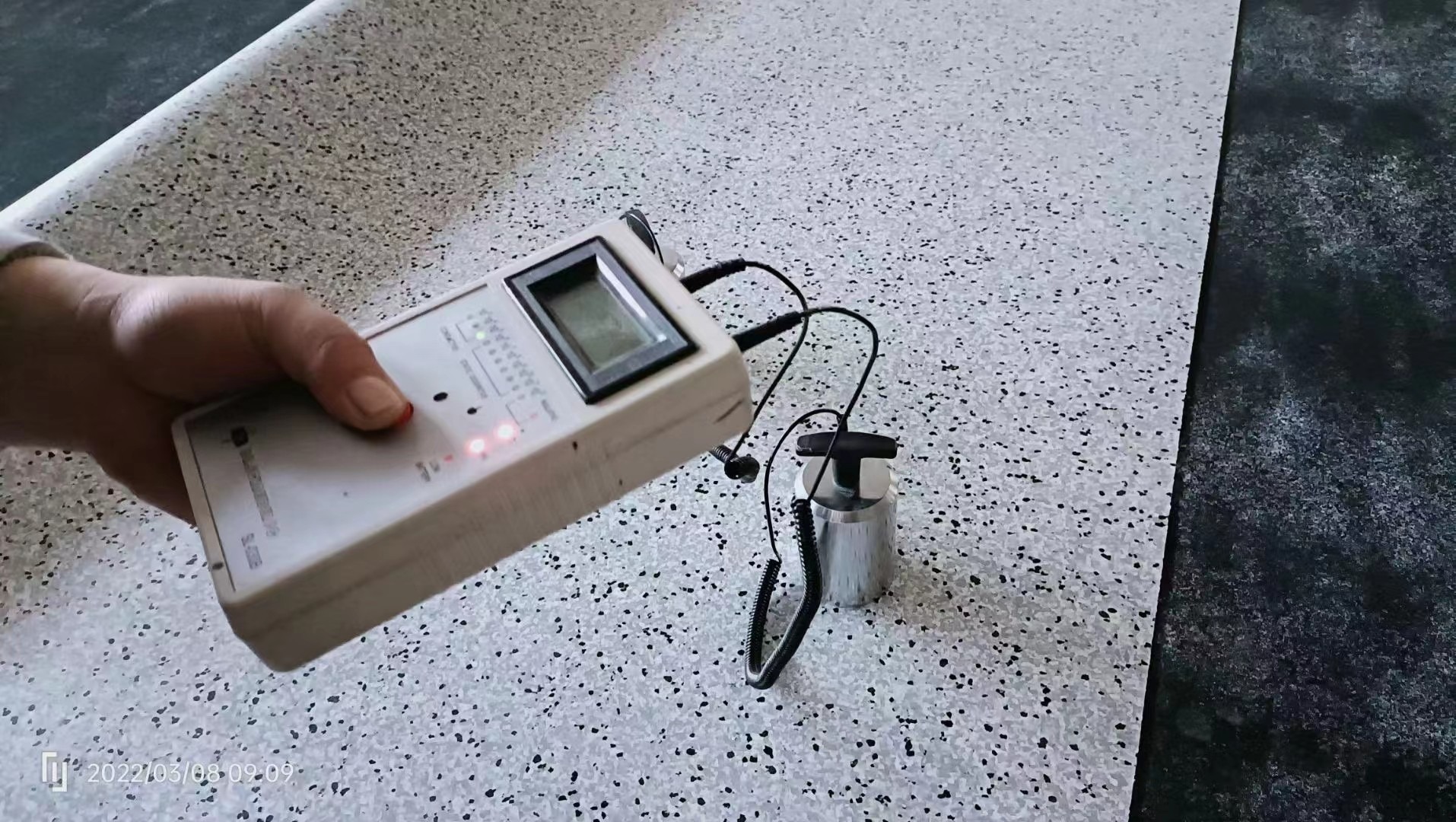

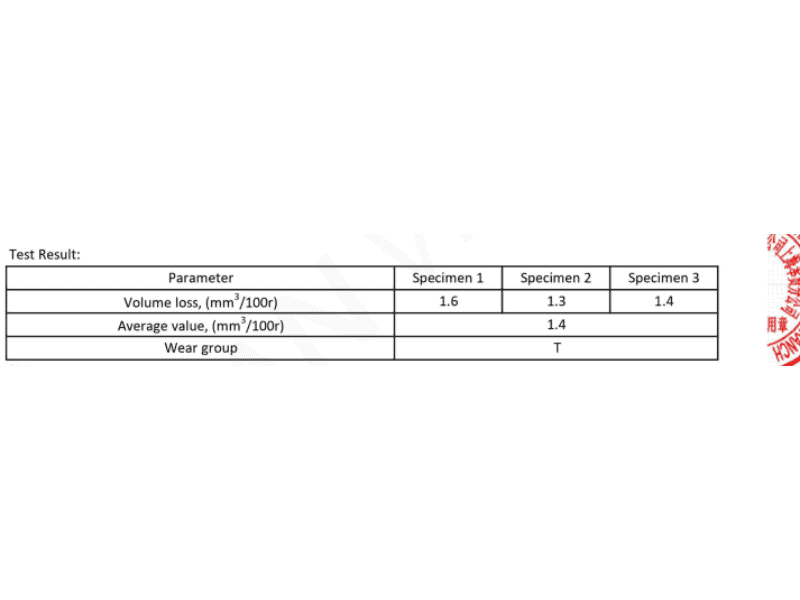

1.Wear Resistance

Homogeneous PVC flooring consists of PVC, fillers, and plasticizers—not pure PVC. Wear resistance testing can reveal quality differences: the harder it is to wear down, the fewer inferior materials are present, indicating better quality.

European Wear Resistance Standards (EN 660-2)

T Class: Nearly zero wear (typically found in heterogeneous PVC flooring with a pure PVC wear layer).

P, M, F Classes: Lower wear resistance (common in homogeneous PVC flooring).

Important Note:

Higher wear resistance = Higher PVC content → Lighter weight per unit area → Higher cost.

Some tenders specify maximum weight limits to ensure the quality of the product.(2800g-3100g)

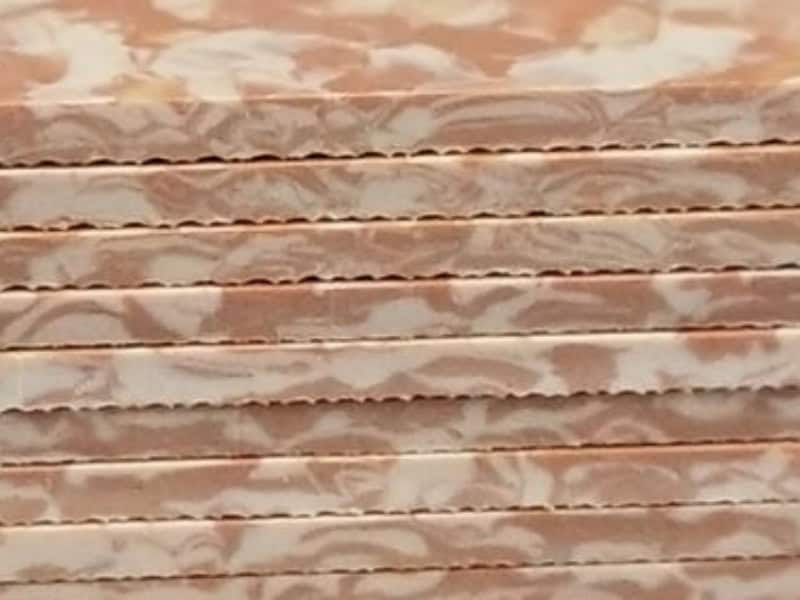

2.Visual Inspection

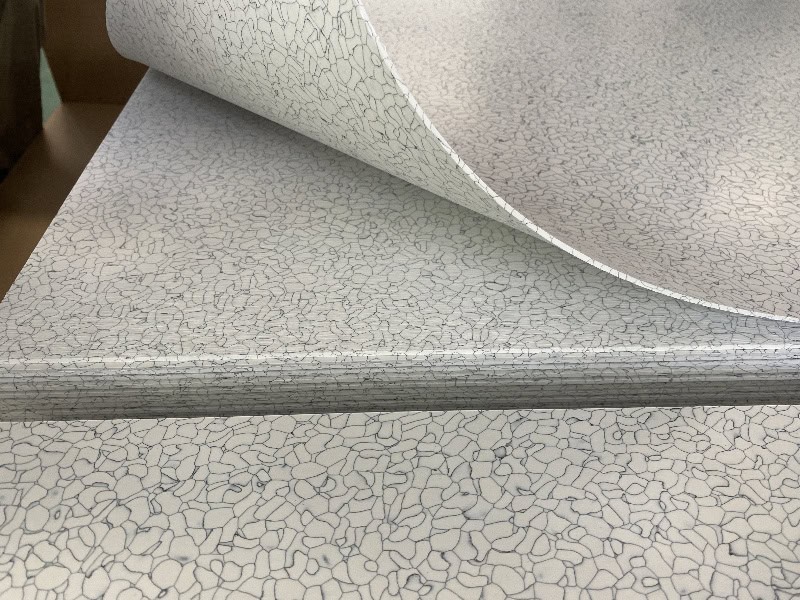

Cross-Section Analysis

Uniform texture: High-quality flooring has a consistent material composition throughout.

Powdery middle layer: Indicates excessive filler (e.g., calcium carbonate).

Micro-pores: Suggests low density and poor compaction.

Bend Test (Cold Weather Performance)

In cold temperatures (below 15°C), bend the flooring:

Cracks or breaks = Poor flexibility (low plasticizer content).

No damage = Good flexibility (better formulation).

3.Directional vs. Non-Directional Patterns

Non-directional patterns (uniform in all directions) indicate higher manufacturing precision and slightly better quality.

Directional patterns may have minor inconsistencies in wear resistance.

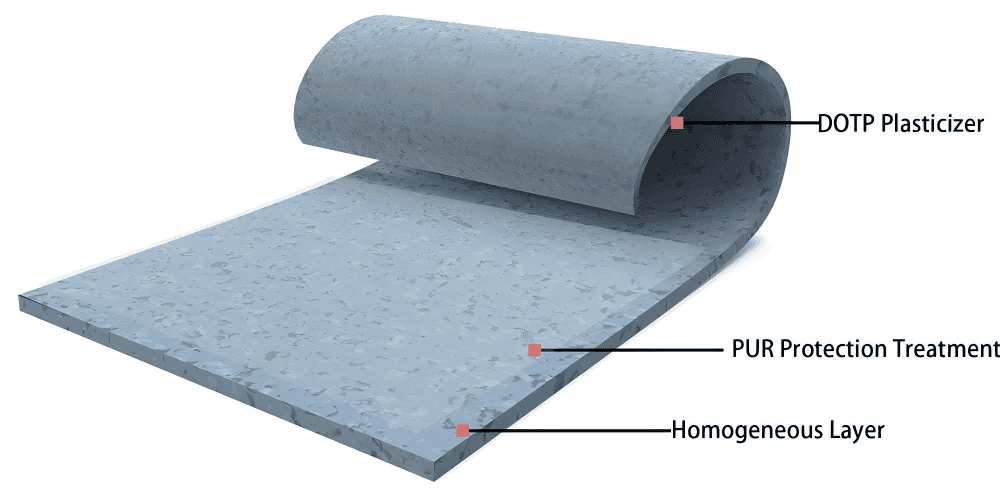

4.Surface Treatment: PU/PUR/UV coating

PU (Polyurethane Coating)

A surface-level sealant that fills microscopic pores to prevent staining.

Disadvantage: The protection wears off over time.

PUR (Polyurethane Deep Treatment)

Applied via calendering, penetrating the entire thickness of the flooring.

Advantage: Maintains stain resistance even after surface wear.

UV coating

UV coating exhibits high hardness, good wear resistance, high transparency, and excellent scratch and friction resistance.

UV coating can decompose harmful substances during the production process, does not contain any volatile substances, and is a truly green and environmentally friendly coating.

Common in premium European-standard homogeneous PVC flooring.

5.Additional Factors Affecting Price

Design Complexity

Multi-color patterned flooring > Standard three-color designs.

Anti-Static Properties

Anti-static homogeneous PVC flooring is more expensive than standard versions.

6.Installation Considerations

Minimum temperature: 15°C (below this, PVC hardens, making installation difficult).

Expansion rate: ~0.4% (4x higher than heterogeneous PVC flooring due to lack of fiber reinforcement).

Standard requirements (subfloor flatness, humidity control, adhesive application) still apply.

Conclusion

To ensure you’re selecting high-quality homogeneous PVC flooring, check:

✅ Wear resistance (T/P/M/F class)

✅ Uniform cross-section (no powdery layers or pores)

✅ Non-directional patterns (better consistency)

✅ PUR/UV treatment (superior long-term stain resistance)

✅ Cold flexibility (no cracking when bent at low temps)