Anti-static PVC flooring is a special flooring material widely used in electronic manufacturing, data centers, medical facilities, laboratories, and other fields. Its primary function is to protect sensitive equipment and products from electrostatic discharge (ESD) damage through conductive properties or static dissipative. With the rapid development of the global electronics and high-tech industries, the anti-static PVC flooring market showed strong growth momentum in 2024. This article will analyze the market status in 2024 and look forward to the market trend in 2025.

Market size and growth

In 2024, the global anti-static PVC flooring market will continue to expand, mainly driven by the electronics manufacturing industry, data center construction, and medical facility upgrades. According to market research data, the annual growth rate of the anti-static PVC flooring market is expected to be between 6% and 9% in 2024, with the Asia-Pacific region (especially China, India, and Southeast Asian countries) becoming the fastest-growing market.

Main application areas

Electronic manufacturing industry:

Anti-static PVC flooring protects precision components from static damage in semiconductor, microelectronics, and consumer electronics manufacturing workshops.

Data center:

With the popularity of cloud computing and big data, the demand for anti-static flooring in data centers has increased significantly to prevent static electricity from interfering with servers and network equipment.

Medical facilities:

Anti-static PVC flooring is used in hospital operating rooms, laboratories, and pharmaceutical workshops to ensure equipment safety and the stability of the operating environment.

Aerospace:

Anti-static flooring protects high-precision instruments and equipment in aerospace manufacturing and testing facilities.

Market competition pattern

In 2024, the leading players in the global anti-static PVC flooring market include Armstrong World Industries, Forbo Flooring Systems, Gerflor Group, etc. These companies have occupied a significant market share through technological innovation, product diversification, and global layout. At the same time, local companies in emerging markets are also rising rapidly, grabbing market share with cost advantages and localized services.

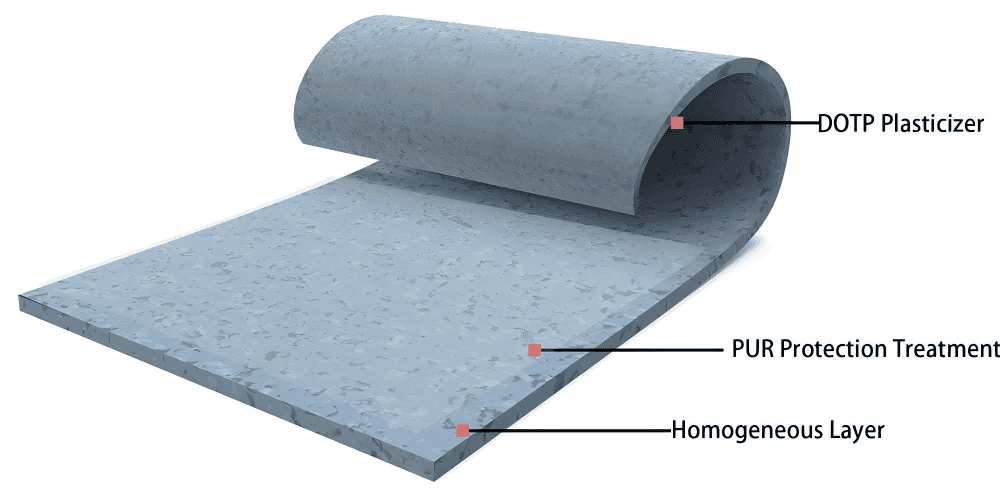

Environmental protection and sustainable development trends

In 2024, the strict implementation of environmental regulations (such as RoHS) has driven anti-static PVC flooring manufacturers to adopt more environmentally friendly materials and production processes. More low-VOC (volatile organic compounds) and recyclable anti-static PVC flooring products have appeared on the market to meet customers’ demand for sustainable development.

Technological innovation

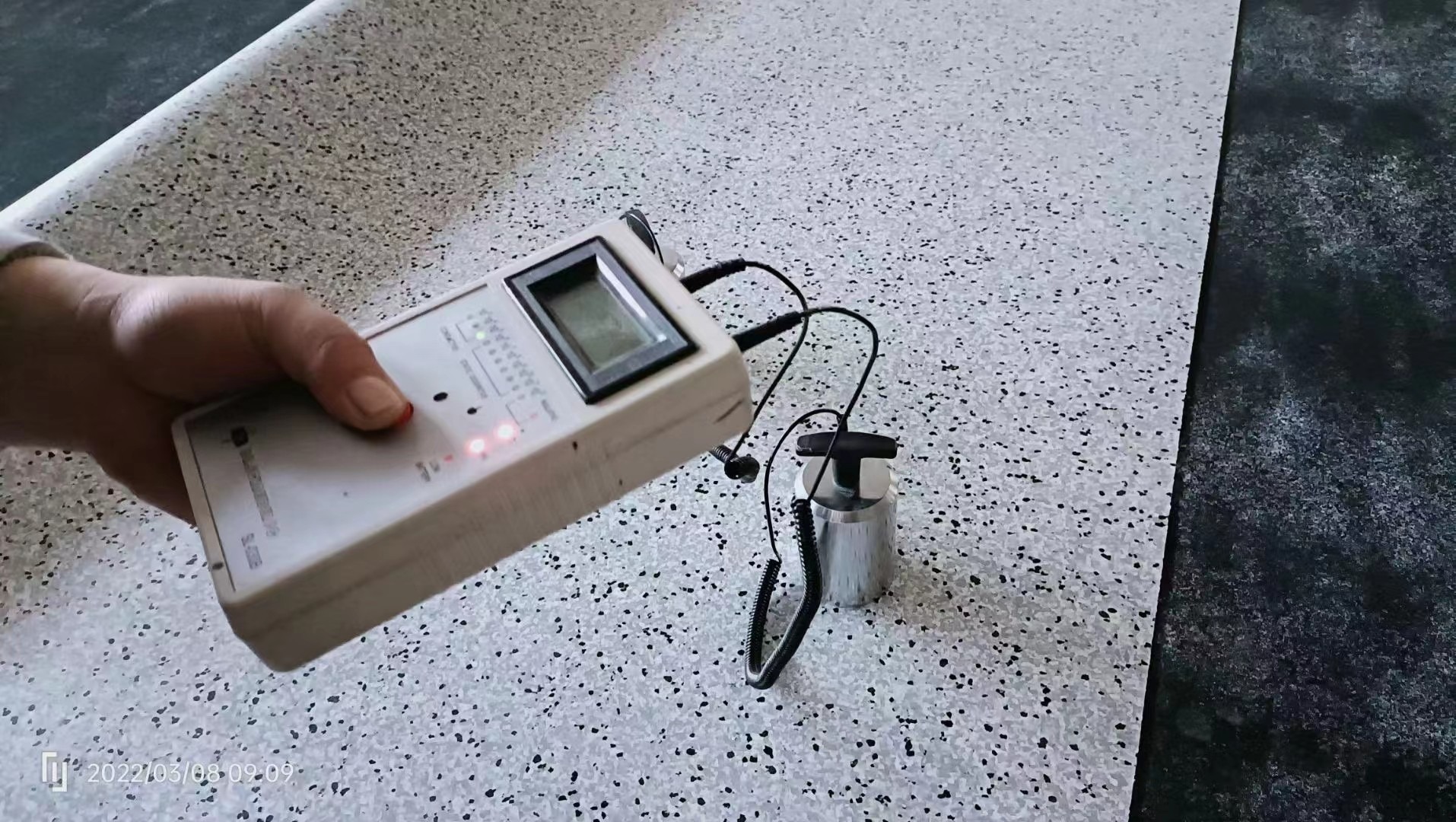

In 2024, the technical level of anti-static PVC flooring will be further improved, mainly reflected in the following aspects:

Higher anti-static performance:

The new anti-static PVC floor has a more stable anti-static performance and is suitable for more demanding working environments.

Wear resistance and durability:

Manufacturers have improved products’ wear resistance and service life by improving material formulations.

Customization demand: Customers’ increasing demand for customization in color, thickness, size, etc. has promoted the diversified development of products.

Outlook of the market trend of anti-static PVC floor in 2025

Market demand continues to grow

In 2025, the market demand for anti-static PVC flooring is expected to grow with the further expansion of the global electronics manufacturing industry, data center construction, and medical facility upgrades. In particular, in the fields of semiconductors, microelectronics, and new energy, the demand for high-performance anti-static flooring will increase significantly.

High performance and multi-functionality

In 2025, the market’s performance requirements for anti-static PVC flooring will improve further. For example:

High-temperature resistance:

Suitable for electronic manufacturing and processing in high-temperature environments.

Antibacterial function:

The demand for antibacterial, anti-static PVC flooring will increase in the medical and food processing fields.

Transparency and aesthetics:

Transparent and beautiful anti-static PVC floors are becoming more popular in high-end electronic manufacturing and laboratory environments.

Green materials and sustainable development

In 2025, environmentally friendly anti-static PVC flooring will become the mainstream market. Manufacturers will adopt more biodegradable materials, renewable resources, and low-energy production processes to reduce their impact on the environment. At the same time, customers will have stricter requirements for environmental certification of products (such as RoHS).

Intelligent and digital transformation

With the deepening of Industry 4.0, anti-static PVC floor manufacturers will accelerate intelligent production and digital transformation. By introducing the Internet of Things (IoT), big data analysis, and artificial intelligence (AI) technologies, companies can optimize production processes, improve product quality, and achieve more accurate market forecasting and inventory management.

The rise of emerging markets

In 2025, the Asia-Pacific region (especially China, India, and Southeast Asian countries) will continue to be the main growth engine of the anti-static PVC floor market. The rapid development of the electronics manufacturing industry and infrastructure construction in these regions has provided a broad market space for anti-static flooring. In addition, emerging markets in the Middle East and Africa are also expected to become future growth points.

Price competition and cost pressure

In 2025, raw material price fluctuations and rising energy costs may put certain cost pressures on anti-static PVC floor manufacturers. To maintain competitiveness, companies need to reduce costs through technological innovation and large-scale production while providing more cost-effective products.

Mergers and acquisitions and industry integration

In 2025, competition in the anti-static PVC floor market will be more intense, and the trend of industry integration will be apparent. Large companies may expand their market share by acquiring small and medium-sized enterprises while obtaining technological advantages and customer resources.